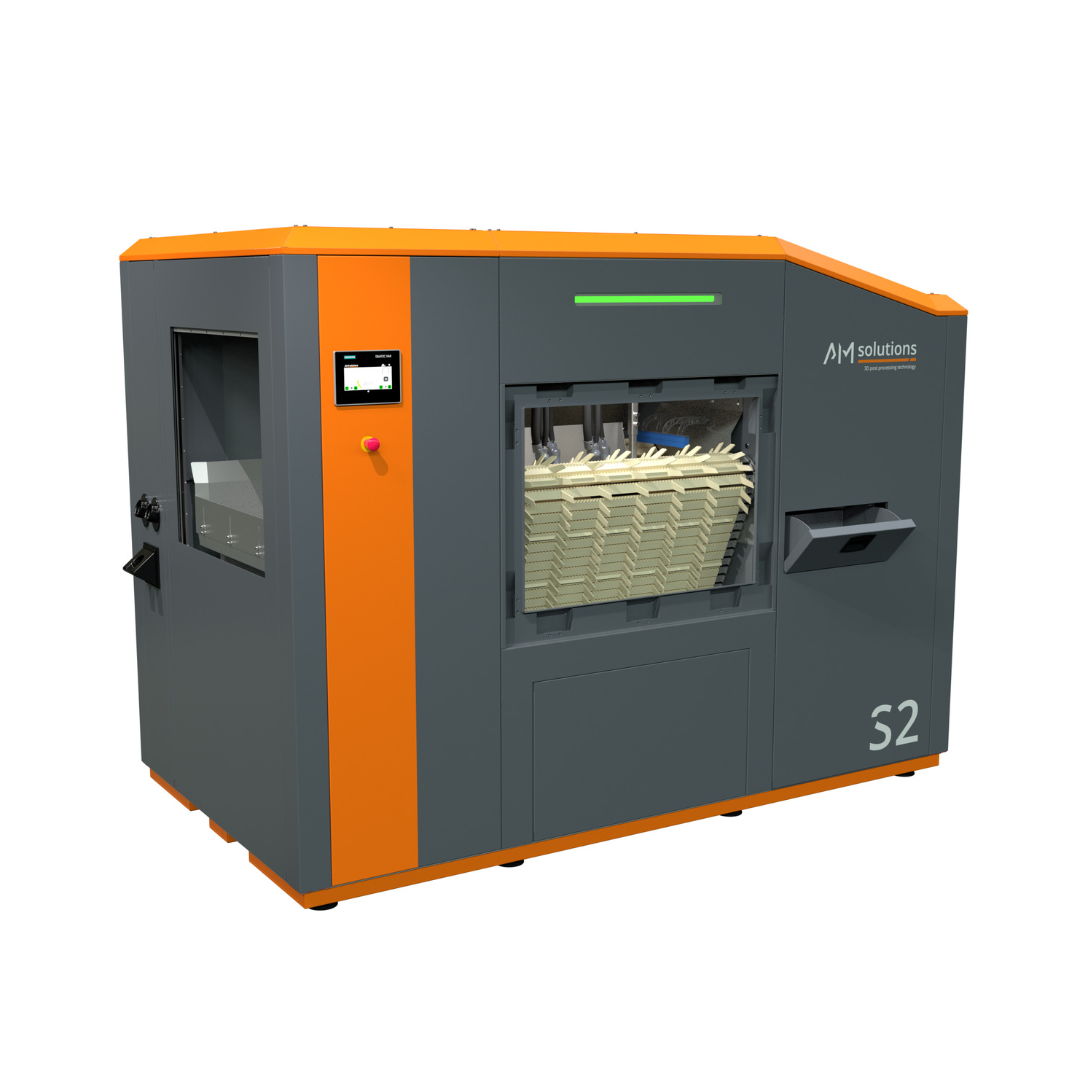

S1 (Series 2) – Automated 3D Print Post Processing by AM Solutions

The new generation of S1 sets new standards for the post processing of parts from powderbed-based polymer printing processes. The smart plug-and-play solution impresses by being able to perform cleaning and surface finishing all in one self-contained unit. Furthermore, it is also suitable for the surface finishing of de-powdered metal components made from non-reactive metals.

Beside automatic or manual shot blasting, the S1 is capable of automatic and effective removal of residual powder after printing. The constant rotation of the work pieces during the cleaning process ensures repeatable and consistent shot blasting results. The ergonomic design, combined with a process-optimized nozzle placement for automatic operation, rounds off the overall package.

Thanks to its compact and robust design, this multi-talent can be easily integrated into any production environment and offers maximum reproducibility, traceability and cost efficiency.

Beside automatic or manual shot blasting, the S1 is capable of automatic and effective removal of residual powder after printing. The constant rotation of the work pieces during the cleaning process ensures repeatable and consistent shot blasting results. The ergonomic design, combined with a process-optimized nozzle placement for automatic operation, rounds off the overall package.

Thanks to its compact and robust design, this multi-talent can be easily integrated into any production environment and offers maximum reproducibility, traceability and cost efficiency.

Ask our Experts

Features

2-IN-1 Solution for cleaning and surface finishing with easy blast media exchange

Improved basket design for optimal distribution and tumbling of the parts

Specially developed wear protection lining made of non-staining anti-static polyurethane

ATEX conformity

Ergonomic and safe machine operation

Quick changeover from manual to automatic processing

Automatically swiveling blast nozzles for contamination-free loading and unloading

Movable tumbling basket allows for easy loading and unloading though the large front door. Even in the loading position the basket remains completely within the blast chamber to prevent powder spillage.

Media conditioning system for maintaining consistent blast media quality and sizing

Industry leading process monitoring and visualization thanks to state-of-the-art software and hardware

Specifically developed for polymer powder bed based technologies

Software controlled process automation with up to 30 recipes

Optimized air flow for minimum powder deposits in the blast chamber

Developed in collaboration with industry leading 3D printing experts

Industry 4.0 ready

Specifications

Dimensions of blast chamber

1,050 x 1,150 x 960 mm (w x d x h)

Number of blasting nozzles

2

Dimensions of workpiece tray

880 x 365 mm

Usable volume basket

2-25 Liter

Dimension of rotating basket

400 - 650 mm

Noise level

≤ 78dB(A)

Blasting media recommendation

GP30, GP60, RPB-E30, RDP

Watch the Video

https://www.youtube.com/watch?v=zxKntXEpSGw