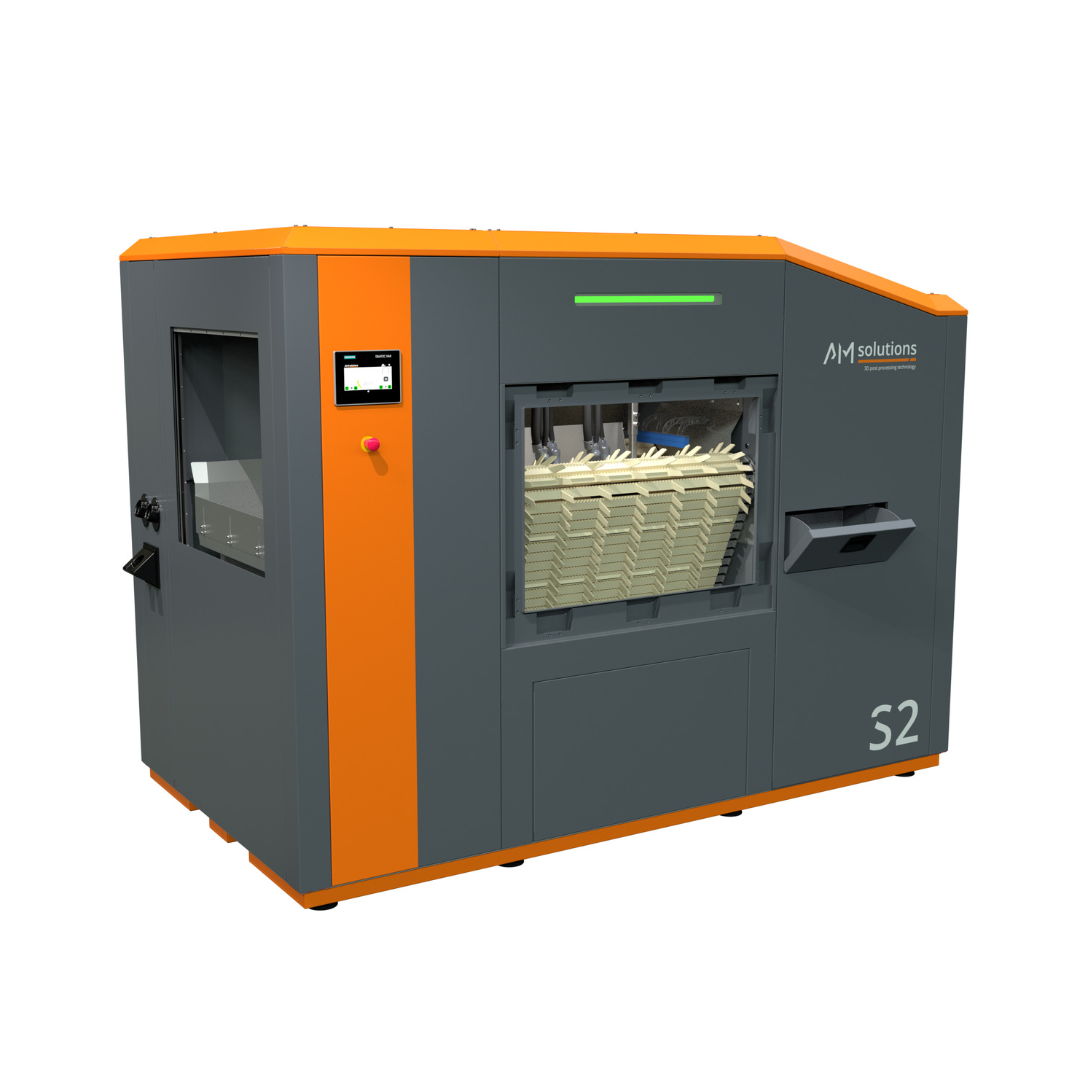

S2 – Automated 3D Print Post Processing Station by AM Solutions

Unique parts handling and fully automated post-processing

Just place your plastic components, produced with powder-bed printing systems, into the S2 – everything else takes place in a fully automatically.

The special loop belt allows single piece flow and particularly gentle work piece handling. This ensures uniform cleaning, surface homogenization and / or peening of the work pieces in continuous mode operation. The integrated blast media recycling system guarantees consistently good processing results.

Just place your plastic components, produced with powder-bed printing systems, into the S2 – everything else takes place in a fully automatically.

The special loop belt allows single piece flow and particularly gentle work piece handling. This ensures uniform cleaning, surface homogenization and / or peening of the work pieces in continuous mode operation. The integrated blast media recycling system guarantees consistently good processing results.

Ask our Experts

Features

Gentle part handling and uniform blast processing due to the unique continuous loop belt design

No discoloration of parts due to the polyurethane loop belt and blast media conditioning

Automated processing of complete print jobs, independent of the printer manufacturer

Monitoring of the blasting process ensures reproducible blasting results and consistent quality

Efficient blast media recycling

Compact design with plug-and-play connections

Integrated sound insulation with special door seals

Specifications

Dimensions of loop belt:

L = 1,000 mm, Ø = 335 mm

Number of blasting nozzles:

4

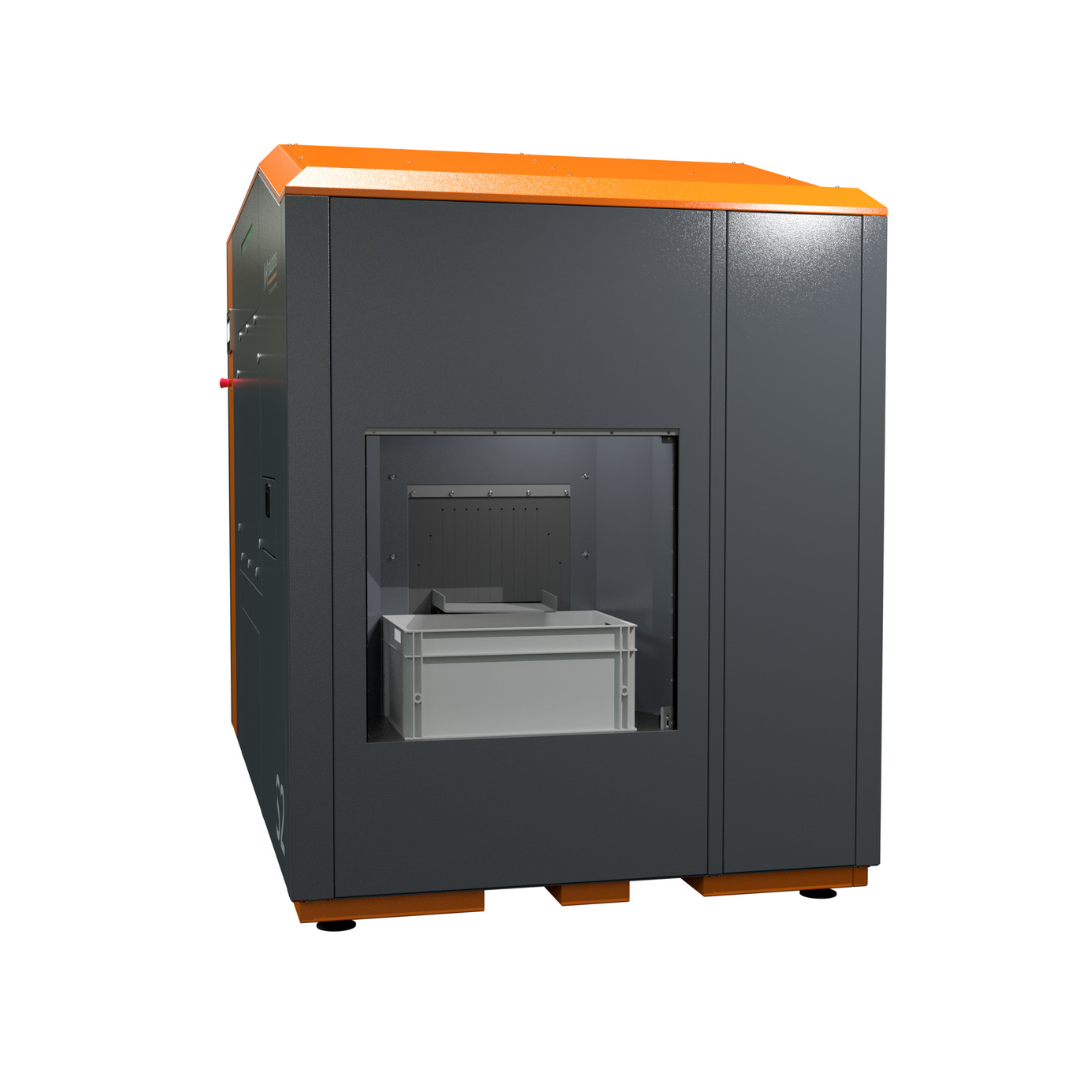

Batch volume:

70 liters of bulk material

Blasting agent replenishment:

20 liters

Noise level:

< 78 dB(A)

Blasting media recommendation:

GP30, GP60, RPB-E30, RDP