S3 Duo – Automated 3D Print Post Processing Station by AM Solutions

Process complex components efficiently and fully automatically

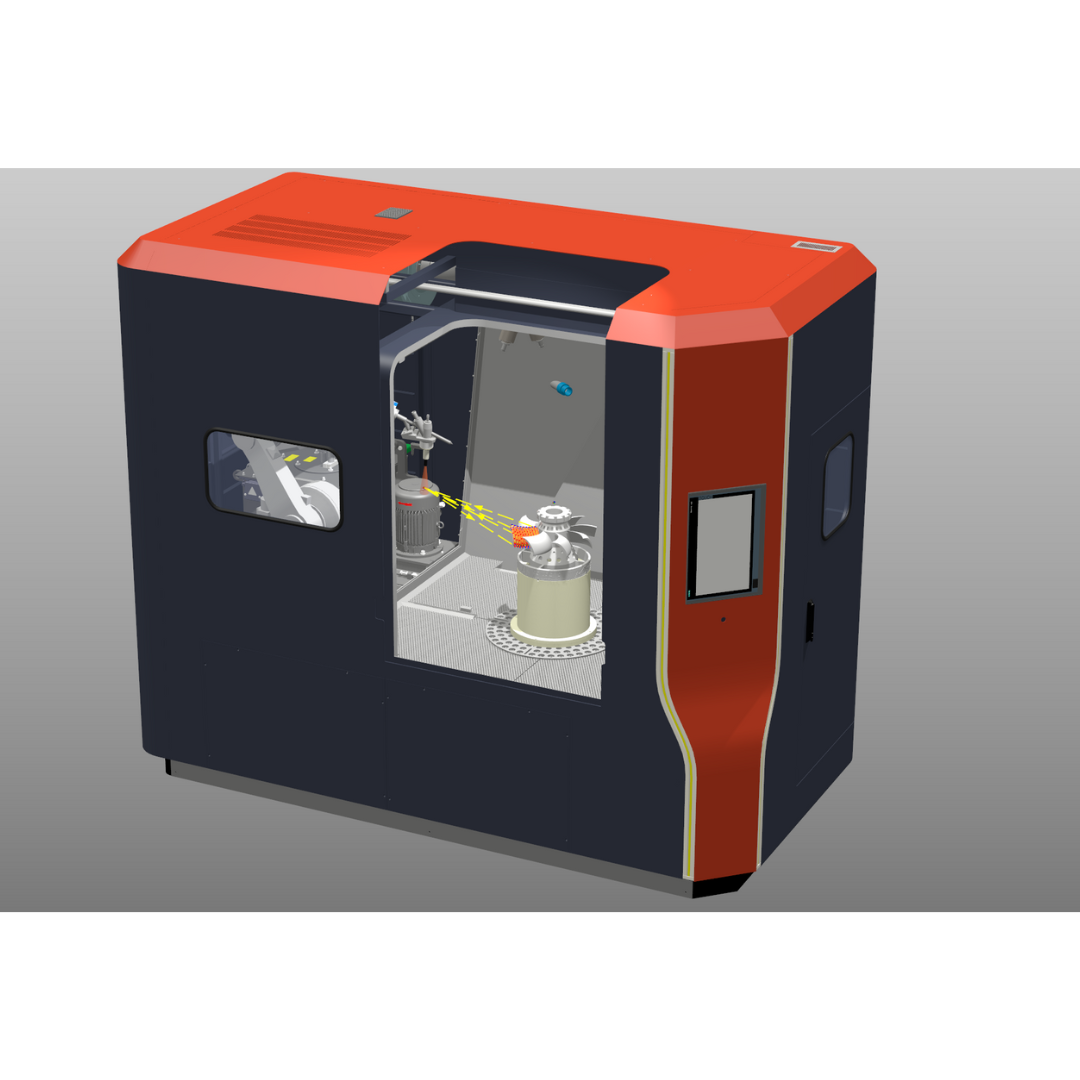

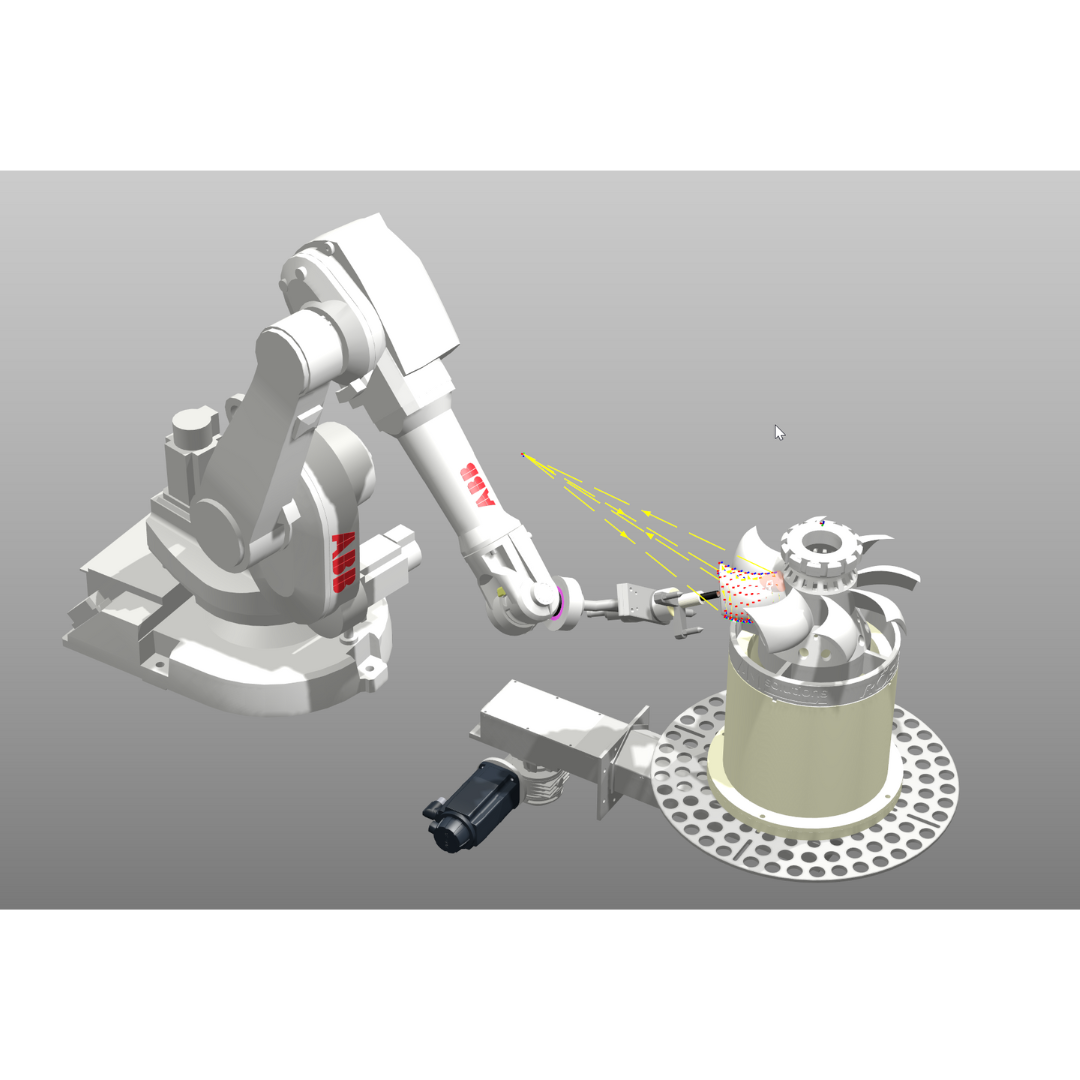

The S3 by AM Solutions plug-and-play system was specially developed for wet blasting applications, which is also available as a dry-jet solution on request. The integrated, robot-guided operation allows the targeted, gentle processing of large and complex work pieces made from metal or plastic materials. At the same time, the continuous monitoring of all process parameters guarantees a high degree of process safety. The fully automatic removal of residual powder and surface finishing achieves a high degree of sustainability and ensures absolutely repeatable results. Furthermore, the large blast chamber door on the front permits access through the machine roof enabling loading/unloading the work pieces by crane.

In addition, the wide range of equipment options, including simplified robot programming, ensure a great deal of flexibility thanks to an innovative playback process. An intuitive and intelligent control system balances the profile.

The S3 by AM Solutions plug-and-play system was specially developed for wet blasting applications, which is also available as a dry-jet solution on request. The integrated, robot-guided operation allows the targeted, gentle processing of large and complex work pieces made from metal or plastic materials. At the same time, the continuous monitoring of all process parameters guarantees a high degree of process safety. The fully automatic removal of residual powder and surface finishing achieves a high degree of sustainability and ensures absolutely repeatable results. Furthermore, the large blast chamber door on the front permits access through the machine roof enabling loading/unloading the work pieces by crane.

In addition, the wide range of equipment options, including simplified robot programming, ensure a great deal of flexibility thanks to an innovative playback process. An intuitive and intelligent control system balances the profile.

Ask our Experts

Features

Available as wet or dry blast system

Robot-guided, automatic processing

"L" shaped door allows work piece loading via crane

Integrated media conditioning system

Closed loop circulation for media (and process water, including conditioning)

Small footprint

Selective processing of the workpiece surface possible

Application of a pre-finish as well as final finish with a wet blasting process

By creating a protective layer on the work piece surface, wet blasting is extremely gentle

Easy operation with intuitive controls

Simple programming with CAD files or an optional playback function

Specifications

Turntable speed:

0 - 100 RPM

Blast nozzles:

1 or 2 nozzles with Ø 6 - 16 mm

Positioning tolerance of robot arm:

< 0.25 mm

Repeatability tolerance of robot arm movement:

< 0.08 mm

Ambient temperature:

+5 to + 40 °C